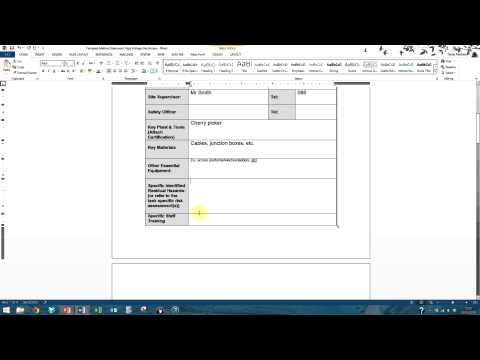

Hello and thanks again for attending one of our safety statement templates. We may watch some of the other videos, but if not, does it really matter? This is the one on how to completely meta statements that we supply within the trade type and construction type safety statements. So, if we just exit out of this screen, we can have a look. Good! Here, you have high-voltage electricity statements. This is when we customize all of the area videos from the electrician safety safe himself. We use this as the best thing today. Let's just open this one up, and we're already from earlier on. Now, if you have a look down here in the mountains, you will see that in part 7, the appendix, we have template medicine for clients. That's the one we want to get him, so we'll just scroll straight to everything else. We come into the appendix template. It is possible to type directly into this area if you want, 6x and so on. However, that means it's being used up when you have to use it again. The best thing to do here is actually to copy this out into a new document and save it as your own meta statement. Then you look ready for as many clients as needed. Let's highlight this text document. So, now we have it set up in a brand new document of its own as a template mentor 7. I should point out here that this is not a romantic statement. This template is from the Construction Industry Federation (CIF). They make it freely available for people to use at their desire for private from providing this. It's widely accepted on building sites and in various different environments. So, as we have it here blanking ready...

Award-winning PDF software

Free method statement for welding Form: What You Should Know

We include safety procedures in all the Welding Works. The following three welding tests are applicable in conducting welding tests for pipe welding, pipe welding (mahogany) and other pipe welding applications of structural materials: 1.) The welding test apparatus: The welder should have a working welding machine, which can be of the same type of welding machine or a modified version of the same type of welding machine. Welding must be performed at the welding station, using the same equipment, under the same conditions as welding on steel pipes. 2.) Welding process: Welding must be performed in the following ways: a.) By continuous welding of tubes of different thickness; b.) Without interruption in welding: All welding is stopped and the weld-in must be finished, c.) by welding of the tube. 4. Safety procedures and special tasks associated with Pipe Welding: Safety precautions for pipe welding apply especially in weld-in of pipe. The following must be followed: a.) Safety precautions to be observed should be taken while welding on pipe and when welding pipes on top of pipe, even if the welding is conducted with a metal tube, and it is installed on a galvanized metal frame or galvanized pipe. b.) All welding must be conducted in a safe working place in the absence of hazards: · The welding station must have a sufficient space and safety measures must be taken for protection of the welding process. The following special tasks should be taken: c.) If safety precautions are not used, it may lead to a loss of the weld and that may have serious consequences; d.) When welding in the galvanized pipe frame, to avoid possible dangerous vibration and possible accident; e.) When welding pipes of different diameters, to avoid possible loss of material and that may have serious consequences; f.) If welding steel pipe and pipe fittings where tube diameter is more than 1 cm, the weld-in should be done in a working station equipped with suitable safety equipment. 5. Welding process: a.) The welding process in pipe welding takes place by welding two tube of different diameter, weld with a welding machine and final weld. b.) The final welded tube must conform to the shape of the pipe and conform to the length and width of the pipe. 7.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Hot Work Permit, steer clear of blunders along with furnish it in a timely manner:

How to complete any Hot Work Permit online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Hot Work Permit by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Hot Work Permit from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Free method statement for welding