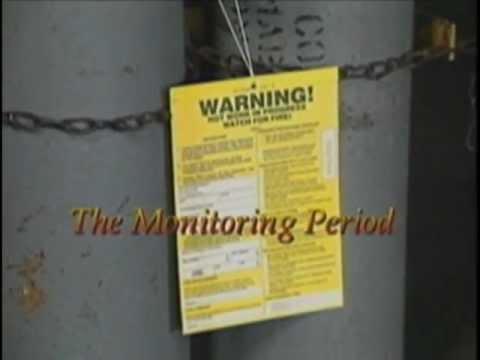

After the one-hour watch is complete, the supervisor will set in motion a three-hour monitoring period. History shows that fires start after everyone's packed up and gone home. What happens often is there might be concealed spaces where a spark gets down into a concealed space and just kind of smoulders there. It's not creating a lot of smoke, but the fact that it's a concealed space lets the heat build up and that heat builds up to a point where it ignites. The monitoring period is the failsafe for this. Some of the things you can use for your monitoring period would be to use security guards or assign certain personnel to keep an eye on it. Even production personnel in that area can keep an eye on the vicinity where the hot work was done. And then there's always the smoke detection system - the point is to have someone or something alert you before a fire gets out of hand. When the three hours are completed, the hot work supervisor makes the last round, and if all's well, signs off on the permit and files it. At this point, everything that was moved out can be moved back in.

Award-winning PDF software

Hot Work Permit Template hse Form: What You Should Know

Work zone Safety System — HESSE WORLD The Work zone Safety System helps ensure safe, responsible and reliable use of equipment in designated work zones. The system uses safety features on the equipment to control the hazards for both the employee and the workplace. Work zone Safety Features include: Access control systems, ventilation controls, safe work practices, and other systems. Access Control Systems — HESSE WORLD Use safety systems to protect people and materials. Safety systems are provided and maintained to monitor the location, usage and location of all power and plumbing, fire alarm and communication, mechanical, heat and environmental controls. Thermal — CHECKLIST Protect workers from heat stress and heat-related illness. This includes: Hot work controls and sprinklers in service/operable. (Where HEAT-RELATED Illness — HESSE WORLD Determine cause of heat illness. Check for signs and symptoms of heat illness as heat stress is often an early symptom. Signs and Symptoms — HESSE World Check for signs and symptoms of heat illness: 1) Increased heart rate and pulse rate 2) Stiff muscles 3) Fatigue 4) Shivering 5) Sweating 6) Fatigue 7) Decreased activity and general feeling of tiredness Temperature and ventilation controls — HESSE WORLD Heat stress or heat illness can develop from the temperature and ventilation control(s) used in a work environment to protect people and materials from excess heat loss, increase employee comfort, prevent injury from heat exposure (or overheating) and manage hazards created by the building (environment). Ventilation — HESSE WORLD Use ducting and exhaust systems to manage heat loss and ventilation. Ventilation systems are available for mechanical, electrical, and ventilation purposes. Ventilation — HESSE WORLD Protect people, materials, and equipment from excessive heat loss, heat exposure and exposure to harmful levels of smoke. Heat and smoke detectors are also available on all of our equipment Hot Work Controls — HESSE WORLD Control workers' exposures to hazardous heat. Use ventilation system(s) and heat detectors to keep work area heat from increasing. Proper ventilation should keep workers well covered, cool, and toasty all day long. In some areas it can be tricky to identify the appropriate type of ventilation, such as mechanical, electrical, or even natural ventilation.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Hot Work Permit, steer clear of blunders along with furnish it in a timely manner:

How to complete any Hot Work Permit online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Hot Work Permit by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Hot Work Permit from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Hot Work Permit Template hse